Professionalism, Quality, Certification

Profab was established in 2005, 20 years of deep ploughing stainless steel precision parts manufacturing, with a number of 5-axis CNC production lines and perfect quality inspection system, and cooperation with leading enterprises in automotive, industrial, marine, medical and other fields, and continue to provide high-precision, high-reliability customised solutions.

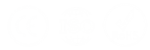

Wide Range

Of Products

We offer rod ends, spherical bearings, ball joints, clevis, threaded rods, and spacers for food machinery, automation, vehicles, and marine use—also supporting OEM/ODM custom manufacturing per drawings or samples.

Advanced

Capabilities

Our manufacturing capabilities include CNC machining of high-tolerance parts, thread cutting (metric, imperial, left/right-hand), TIG/MIG welding, and surface treatments like polishing, passivation, sandblasting, black oxide, and nickel plating.

Professional

Services

Our engineering team offers drawing review and optimization for manufacturability, supports rapid prototyping and small batch trials, and provides branded or neutral packaging with reliable sea, air, or freight delivery.

Turning Tough Specs into Seamless Performance

Comprehensive Custom Stainless Steel Parts Solutions

Equipped with 10+ precision production lines, we deliver high-efficiency manufacturing and tailored support for your needs.

We offer multiple models of stainless steel rod ends like XM/XF, CM/CF, JMX/JFX.

These ss threaded rods are corrosion resistant, dimensionally accurate, and available in a variety of thread types and lengths.

All spacers are made from corrosion-resistant stainless steel and are available in CNC machining.

304/316 stainless steel, 17-4ph optional, inch/metric sizes, male or female, custom service is always available

We provide high-quality stainless steel ball joint linkage and professional solutions to meet the diverse needs of various industries.

They are widely used in industries such as food processing, marine equipment, automation, aerospace, and heavy machinery.

Multi-directional load-bearing components ideal for conveyor tables, cargo handling platforms, and assembly lines.

Your Trusted Partner in Stainless Steel Parts and Hardware

Backed by two decades of manufacturing expertise, we deliver precision-engineered stainless steel components for diverse industrial applications. Our scalable production and responsive global service help your business move faster and grow stronger.

Solar Energy

Automotive Machinery

Medical Industry

Custom Any Stainless Steel Parts for Your Project

Explore the wide-ranging applications of our stainless steel components across demanding industries like automotive, marine, food equipment, and automation.

Laser Cutting

High-precision cutting of stainless steel using a laser beam, suitable for thin materials. Fast cutting speeds and smooth, burr-free edges make it ideal for complex shapes.

Stamping

Shaping stainless steel sheets under pressure using a die. Highly efficient and low cost, suitable for mass production of simple parts.

Bending

Forming a specific angle or shape by bending stainless steel: Forming a specific angle or shape by bending stainless steel. Easy to operate, high precision, adaptable to various thicknesses, and flexible.

CNC Machining Center

Computer-controlled, high-precision machining ideal for complex parts. Supporting multi-axis operation, high efficiency and micron-level accuracy, they are ideal for small-lot customization.

Numerical Control Machining

Automated machining technology for efficient production of a wide range of materials. Fast processing speeds, consistent quality, ideal for medium to large volume production, and high flexibility.

Sheet Metal Welding

Stainless steel plates are joined together by welding to form a complete structure. High strength and sealing, ideal for housings, frames and structural components.

FAQ

What materials are used for Profab's stainless steel components?

A wide range of stainless steel grades such as 304, 316, 410, 17-4PH, etc. are available to meet corrosion resistance, mechanical strength and budgetary needs.

What types of stainless steel parts does Profab offer?

Profab’s full product line includes Stainless Steel Threaded Rods, Rod Ends, Spacers, Clevises, Spherical Bearings, Ball Joints, Ball Transfer Units, Bumpers, Flanges, Radius Rods, Filters, Wheel Hubs, Fasteners, Clamps, Tube Fittings, and more. Profab supports custom stainless steel parts for a wide range of industries—feel free to send us your inquiry!

What surface finishes does Profab support?

Electropolishing; Sandblasting / Bead Blasting; Mirror Polishing; Powder Coating; Passivation; Brushing (Satin Finish); Black Oxide / Blackening (on stainless steel alloys that support it).

Request a Quote

If you already have the drawings, please send email to [email protected] directly for an instant quote.

Work with Profab Machine

Get a Stainless Steel Solution with Easy

Let’s Start Our Cooperation with the 3 steps to start now!

1. Tell Us What You Need

Send us your request with details and share your idea.

2. Get Solution and Quote

We will work on the best solution base on your request and send you a specific quote within 24 hours.

3. Support at All Times

Whether it is before or after the sale, we are always here to support you.

What Our Customers Say